Turnkey Projects

32,5MW Power Plant Brazzaville

The turnkey project in Brazzaville was realized with several companies of the Ogepar group.

This power plant produces 32,5MW for the city of Brazzaville with 10x16VDZC engines on Heavy fuel oil.

The tank park consists of a unload station for trucks, 3x2000m³ storage tanks, 2x30m³ settling tanks ,2x30m³ service tanks and 2x30m³ tanks for gasoil. The treatment of the HFO is done by 5 separators and 2 boosters who are placed in a separate room.

The generators each produce 3,25MW at 6.6kV.

Two transformers of 30MW will transform the tension up to 30KV from which the power will be transported to a substation.

Two auxiliary transformers of 1000KVA are installed to produce the 400V for the auxiliaries.

Power Plant Oleon

The waste fraction of a chemical process is used as fuel for two 8DZC engines on the facilities of our client Oleon (the leading producer of oleochemicals in Europe). As this fuel is the residue of a distillation process, it contains high amounts of free fatty acids and is substantially contaminated. Hence, special attention is given to the fuel preparation consisting of multiple centrifuges, a booster unit and several adapted filters. The engines' fuel injection equipment is also customized to coop with the special fuel. Electricity is generated via a low-voltage alternator and transformed up to 12kV via the 2.000kVA main transformers. Through the high-voltage cubicles with their respective safety features, the power is injected into the local grid. A complete Combined-Heat-Power plant is achieved as also the heat is used making steam (via the exhaust gasses of the engines) and hot water (via the closed water circuit of the engines).

Power Plant Renogen

The project for our client 4Energy Invest (a Belgian based renewable energy company) consists of one 16DZC engine running on refined and bleached palm oil. With a generated power of over 25.000MWh per year, an average electricity consumption of 8.500 families is covered. On top of this benefit, directly and indirectly the new plant will create more than 40 new jobs. The produced heat is recuperated and transferred to 2 nearby companies which will use it to dry wood. Besides the generator set and the mechanical and electrical installation, the complete fuel treatment line including storage capacity is designed, installed and put into operation respecting a very tight delivery schedule. Harmful emissions are avoided as an extended exhaust gas cleaning infrastructure is installed. Doing so, the CO2-emissions will be reduced with 55.000 ton.

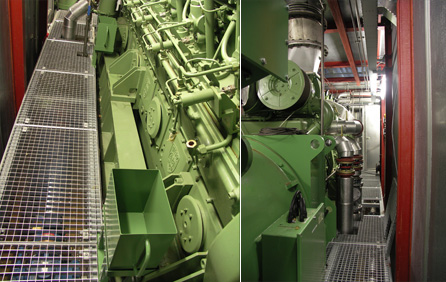

Power Plant Allwinds

The installation and commissioning of 5,5MWh – divided over two 16DZC engines at 1000 rpm - in a narrow space next to a shopping center: that was the challenge for the project with reference "Allwinds" in the Netherlands. As the machinery location was situated directly next to a shopping center, a complete study was dedicated to the sound environmental impact. As a result, special sound-insulating panels are mounted in order to make sure that outside the engine room, no annoying noises are detectable. Additionally, both engines were designed to make sure that the sound exposure of the operators was limited to the strictly minimum.